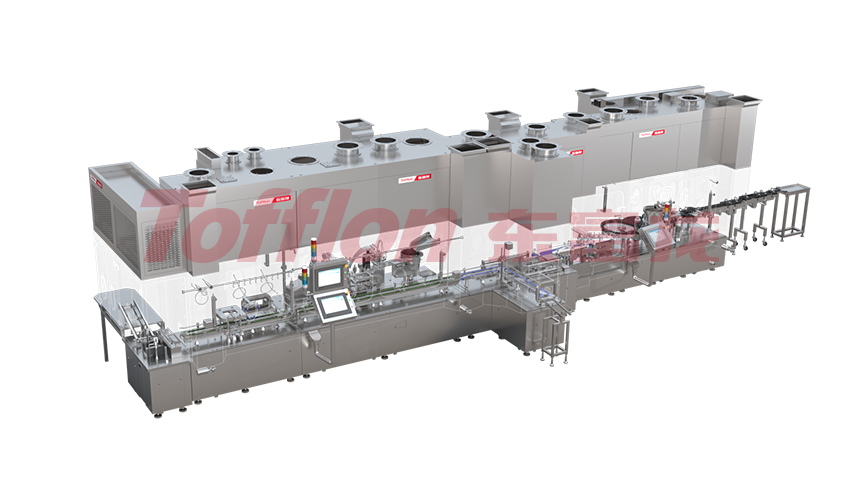

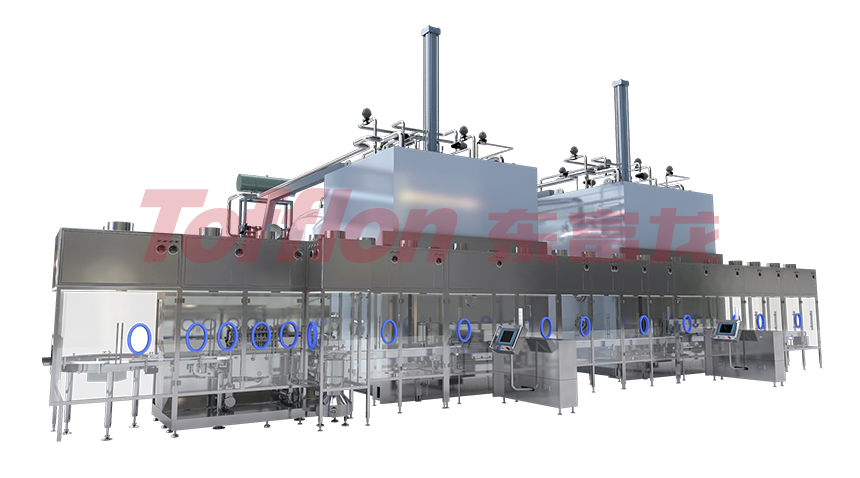

Automatic Aseptic Multi-in-one Filling Line

The automatic aseptic multi-in-one filling line processes three packaging materials: pre-filled syringes, vials, and cartridge vials. They're ready-to-use without cleaning and sterilization. It's suitable for commercial production with different yields like pilot-scale, medium-speed, and high-speed. The line's characteristic is flexible production. Via flexible mold conversion, it supports filling these materials, accelerating drug production safely and flexibly. It offers a low-risk, flexible processing method for aseptic packages, enhancing production efficiency and quality while reducing risks by adapting to various demands.

- The design complies with cGMP, FDA, and EU-GMP.

- Modular and compact design, easy to expand.

- Low investment in the project and short construction period.

- High equipment safety and strong stability.

- Can take into account all RTU packaging materials.

- Multiple filling doses and filling methods are available for selection.

- Integrated control system: highly integrated production data, safety interlocks, and full-process recording.

- The software design meets 21 CFR Part 11 and GAMP 5.

- Can be integrated with an Isolator full isolation system with environmental monitoring or an ORABS system.

-

Vaccines

-

Small - molecule drugs

-

Aesthetic medicine

-

Personalized treatment

-

Gene therapy

-

mRNA

-

Clinical trials

-

CDMO (Contract Development and Manufacturing Organization) business