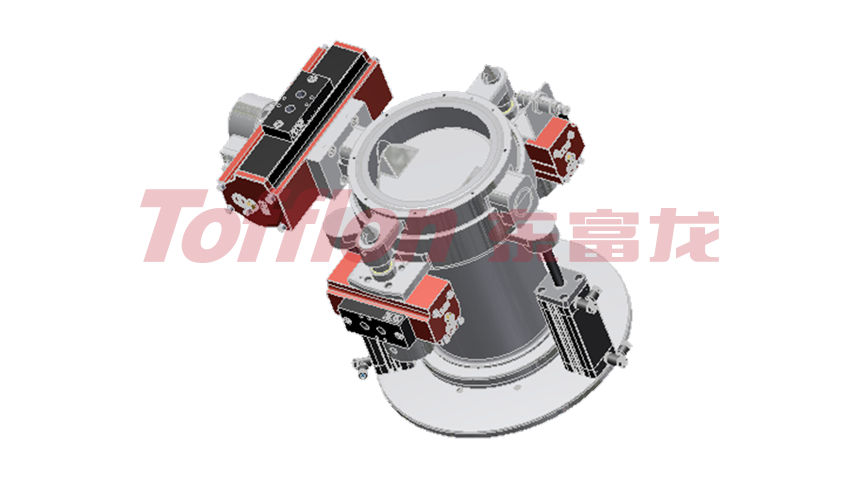

Split Butterfly Valve

Split Butterfly Valve (SBV) consists of an active valve and a passive valve. The active valve is installed at the inlet and outlet ports of the equipment, while the passive valve is installed on the transfer bin. The passive valve cannot be opened independently; it can only be opened after docking with the active valve. The exposed surfaces of both active and passive valves do not contact with the material, making split butterfly valves suitable for the production of highly toxic, allergenic, and reactive materials. This design ensures highly sealed material transport, ensuring operator safety and preventing material cross-contamination.

- 1.Precision machined components

- 2.Optioanl manual/automatic valve structure.

- 3.Safety interlock design prevents independent opening after separation of active and passive valves.

- 4.CIP (Clean-in-Place) design.

- 5.Optional vacuum dust removal system.

-

Ideal for the production of highly toxic, allergenic, and reactive materials in pharmaceutical and food industries.