CIP System

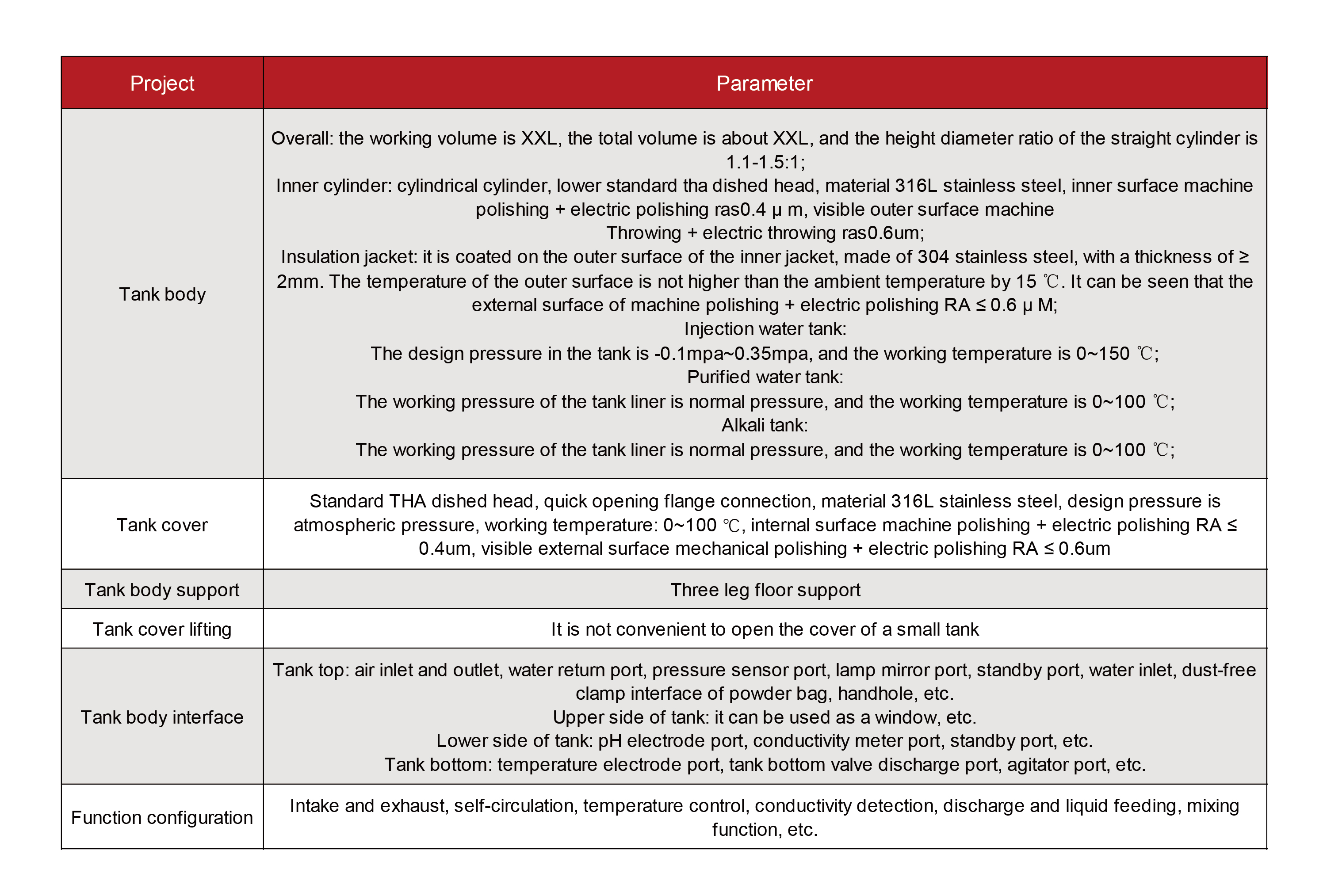

CIP system is mainly used in the cleaning steps of production process to clean the production line with high degree of mechanization and high hygiene requirements to ensure the health and safety of equipment. CIP system can be set with double tank, three tank and matrix CIP stations according to requirements. CIP system equipment includes but is not limited to acid tank, alkali tank, injection water tank, purified water tank, heating system, centrifugal pump, online conductivity detection, etc. The CIP system operates stably, safely and accurately. According to the number, characteristics and production scheduling of cleaning objects, single tank, double tank and multi tank CIP systems can be provided. CIP system has the functions of automatic preparation of cleaning solution, automatic temperature control, automatic determination of cleaning end point, liquid level alarm, and flexible formula management function.

- CIP system has high automation, flexible formula, electronic signature, electronic record, audit tracking and other functions, and operates stably, safely and accurately.

- Customize CIP system settings and provide CIP system according to production requirements.

- CIP system is simple in design, saving labor costs, energy and high cleaning efficiency.

- Solid technology, high quality and complete relevant qualifications.

-

Monoclonal antibody.

-

Vaccines for human use.

-

Veterinary vaccines.

-

Insulin and recombinant protein project.