Formulation System of Emulsion

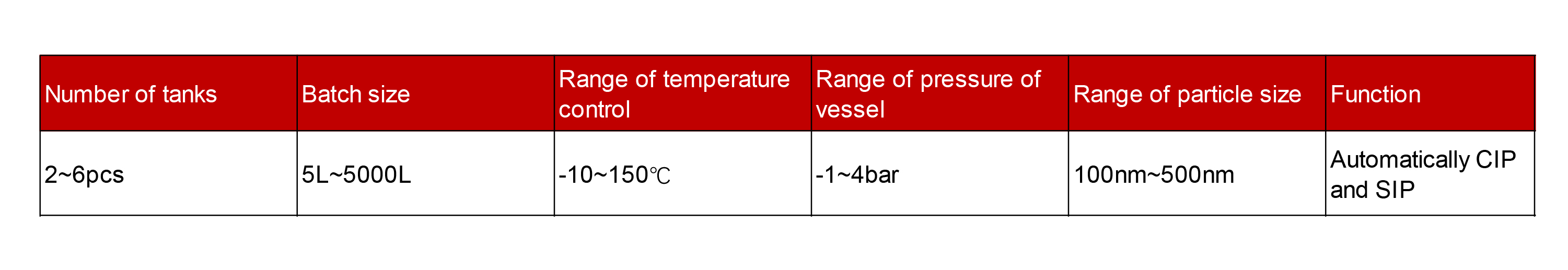

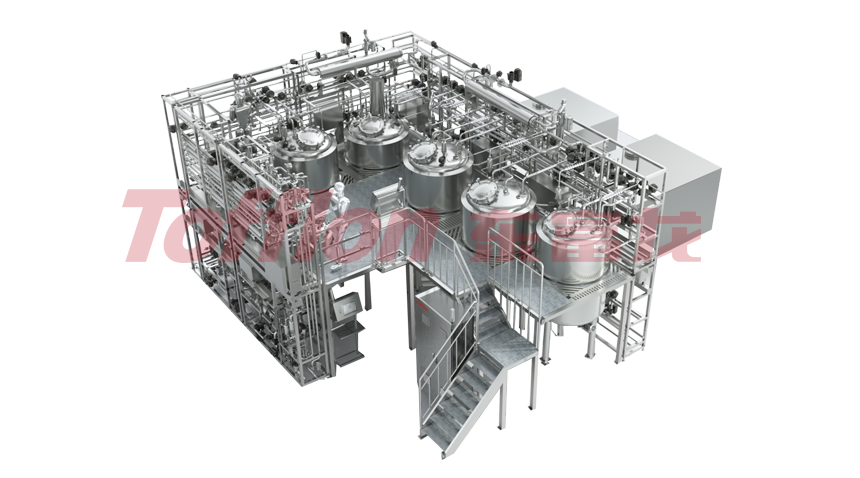

The emulsion formulation is a integrate system which fabricates emulsion product by proportionally mixture the oil phase and water phase then pass through emulsifier and then homogenizer to form the final emulsion. The basic function of this system contains water phase and oil phase preparation unit, emulsifier unit, homogenizer unit and filtration unit. The formulation system is automatically one-touch operation system and the critical process parameters can be controlled and recorded to guarantee high reproducibility and stability. The formulation system is customized and modular design, which can satisfy R&D and commercial production of drug loading emulsion and nutritional type emulsion, such as oral emulsion, injectable emulsion and emulsion for eyedrops. The emulsion fabrication method contains high pressure homogenizer, high-pressure microfluidization and emulsifier.

- Accurately proportionally control of water phase and oil phase to guarantee the efficient of emulsion.

- Nitrogen protest through the whole process to protect the product quality.

- Customized vessel and pipeline design between homogenizer and tanks to guarantee the size distribution of the product.

- Temperature control before and after homogenizer to guarantee the stability of product.

-

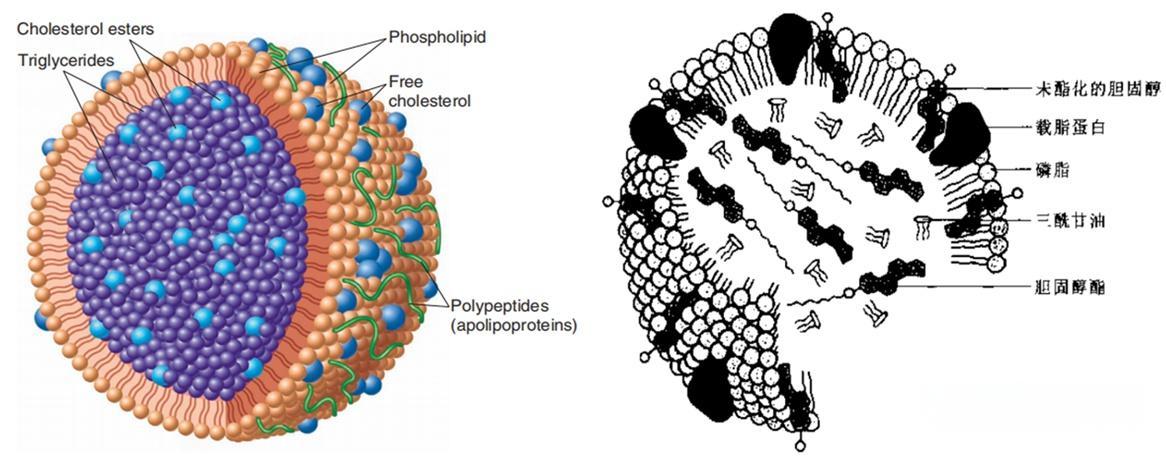

API loading emulsion: propofol fat emulsion; etomidate fat emulsion; alprostadil fat emulsion; aprepitant fat emulsion.

-

Nutritional type emulsion: LCT fat emulsion; MCT/LCT fat emulsion; fish oil fat emulsion.