Formulation System of Microsphere

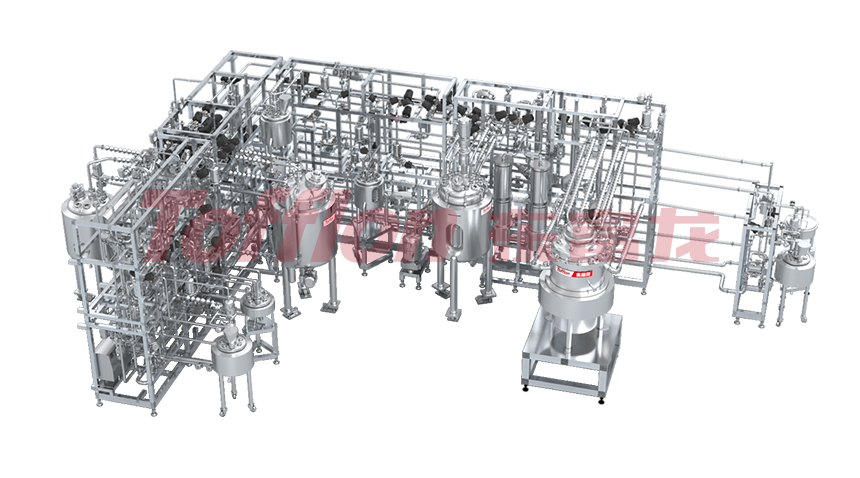

The microsphere formulation system integrates the process steps of raw material dissolving, emulsification, curing to form microsphere, microsphere-liquid separation and drying to fabricate a complete system. The production process of microsphere contains single emulsion method, double emulsion method, membrane emulsification method, phase separation method etc. The system integrates sieving machine, pressure filter dryer and disc centrifuge to separated and wash the microsphere and finally the microsphere is filled by liquid filling machine, powder filling machine. Tofflon have the total solution from microsphere fabrication, preparation, filling to package and have many mature cases of this product. Except formulation system, tofflon can also provide centrifuge, isolator, pressure filter and sieving.

- Personnel protection when adding organic solvent.

- Sterility of the production process.

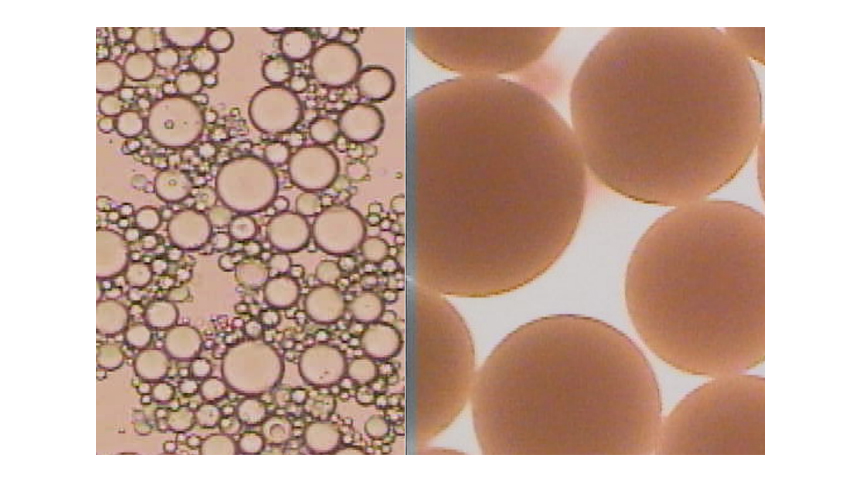

- Particle size distribution control and API encapsulation efficiency.

- Flowrate control of water phase and oil phase.

- Temperature control in microsphere procedure.

- Reasonable filtration and microsphere process.

-

The microsphere system which can satisfy commercial production: triptorelin acetate microsphere; leuprolide acetate microsphere; goserelin acetate microsphere; buserelin acetate microsphere; octreotide acetate microsphere; exenatide acetate microsphere; ripehdone long-acting injection and so on.