Vial Aqueous Injection & Lyophilized Powder for Injection Llinkage System

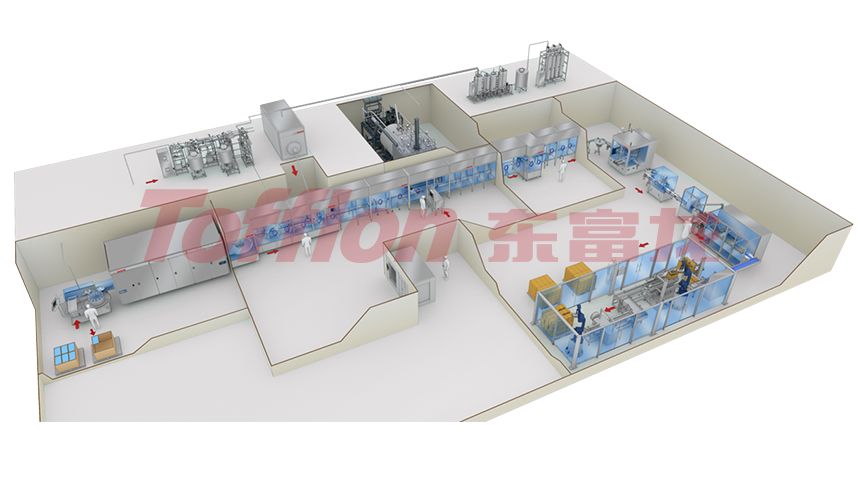

Vial aqueous injection & lyophilized powder for injection linkage line. The vials are firstly washed by the washing machine, and then enter the Sterilizing Depyrogenation Tunnel, in which the sterilizing, drying and depyrogenation operations are completed. Then, the product is filled into vials by filling and stoppering machine, and then sent to lyophilizer for lyophilizing through Auto loading and unloading system, and finally transferred to capping station through Auto loading and unloading system, and then capping operation is completed by capping machine. The vial aqueous injection & lyophilized powder for injection linkage line can be applied to a variety of scenarios such as laboratory, small pilot and large-scale commercial production. It can be flexibly configured according to different production modes. Among the high value-added products in the field of aseptic injection filling, lyophilization has always been a very important part of pharmaceutical production. Lyophilizer linked aseptic injection filling, auto loading and unloading system and isolation system. We can provide tailor-made system solutions according to the customer's plant.

- Adopting Tofflon isolation system to provide safer, more flexible and more reliable filling method.

- The flexible and customized design of Combo platform can realize the common production of vial aqueous injection and lyophilized powder for injection.

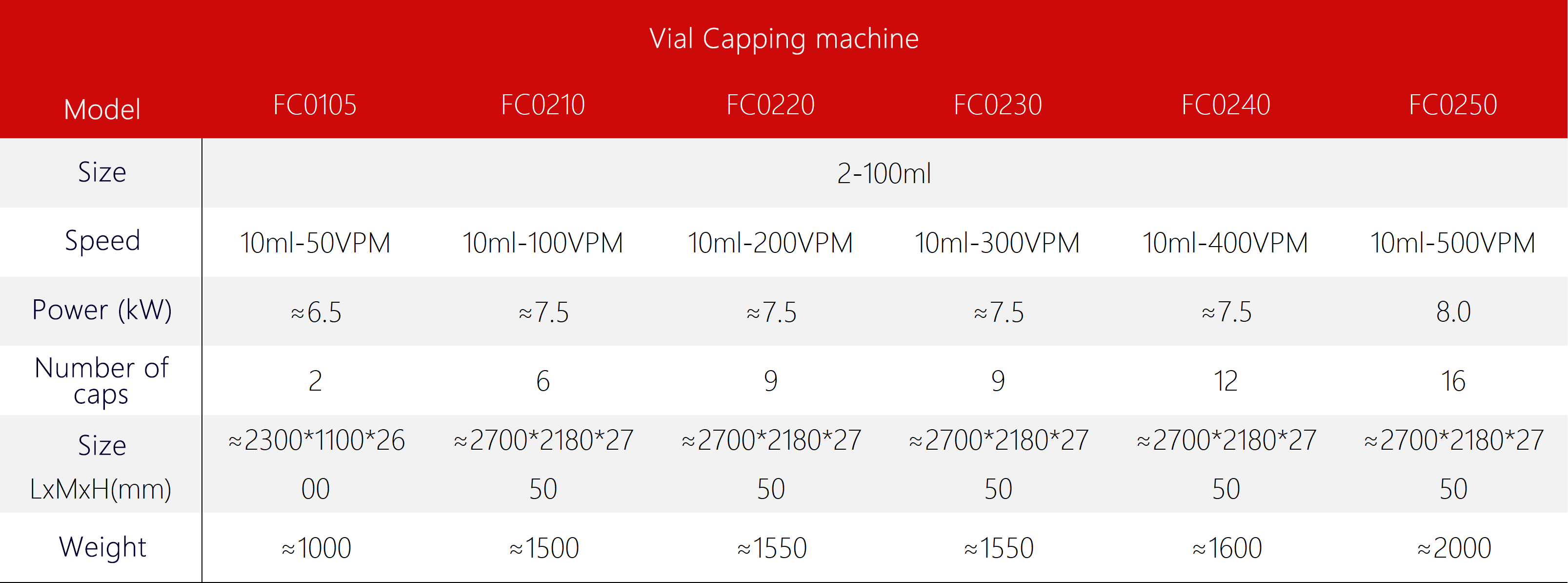

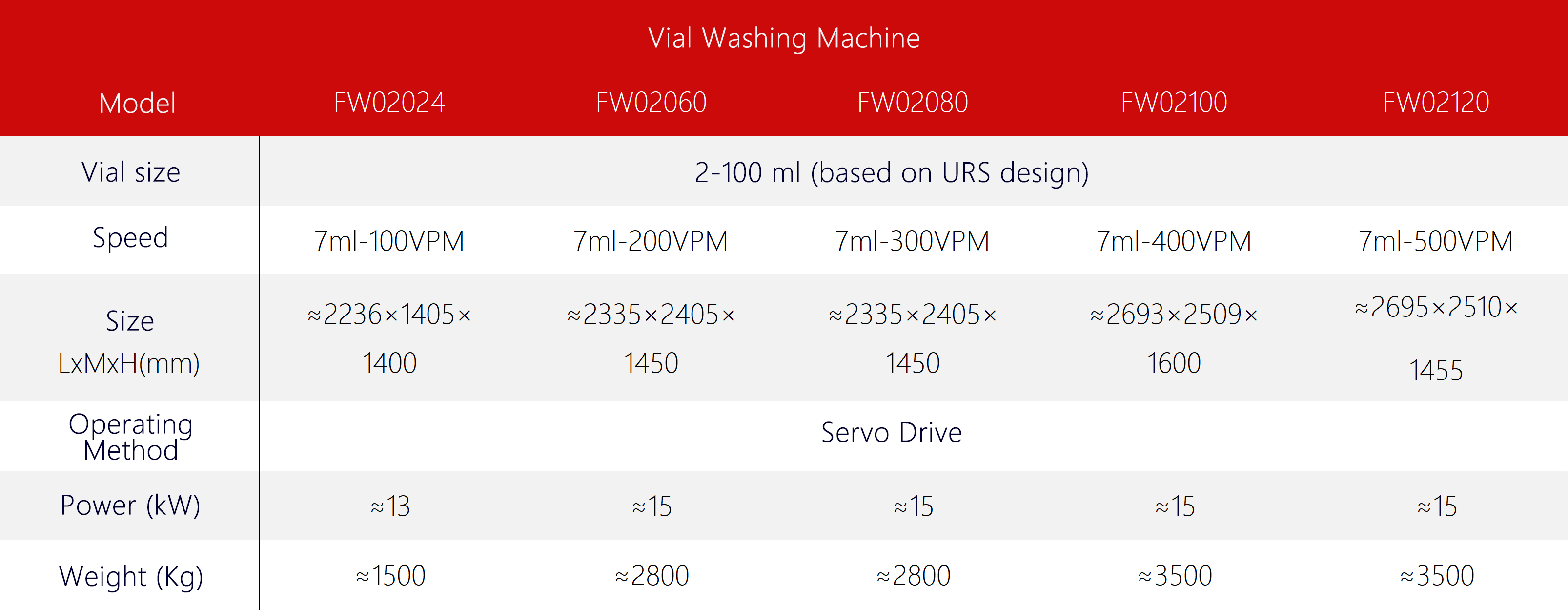

- The equipment has a reasonable production model adaptability, and can be matched with the appropriate equipment for different production capacity.

- With strong single-use technical support capability, it can provide matching single-use filling bags, single-use transfer bags, RTU packages and COP/COC packages.

-

1.Genetic Therapy.

-

2.Large-scale chemical drug production.

-

3.Clinical Trial.

-

4.CDMO Business.