API Freeze Dryer

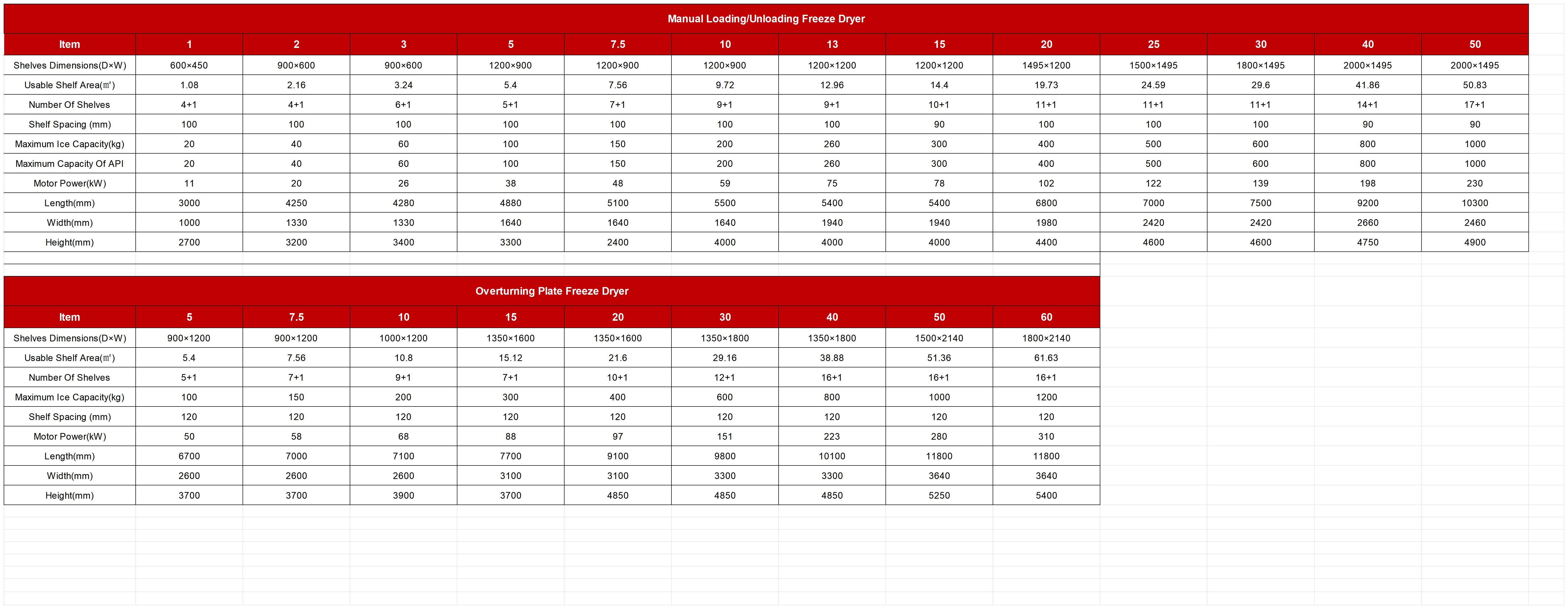

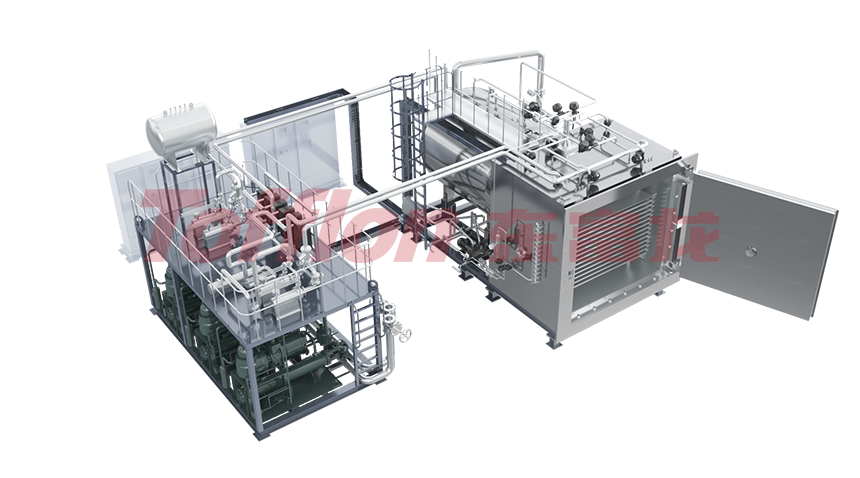

The API(Active Pharmaceutical Ingredient) freeze-drying system is primarily divided into three categories based on market applications: manual loading/unloading systems, semi-automatic systems, and automatic loading/unloading systems. The freeze-drying methods for API solutions include stainless steel tray freeze-drying, membrane frame freeze-drying, and overturning plate freeze dryers for direct freeze-drying. These systems are designed to accommodate various requirements for API freeze-drying solutions, including sterile, non-sterile, toxic, and high-value active substances. Widely utilized in sectors such as pharmaceuticals, medical aesthetics, dietary supplements, and food, these systems enable both small-to-medium and large-scale industrial production of freeze-dried API products.

- A variety of loading/unloading methods are available to meet specific freeze-drying application needs, including:-Loading Methods: Manual loading, AGV trolley tray loading, ALS Plus trolley insertion loading, closed loading for overturning plate freeze dryers, and robotic arm tray automatic loading.-Unloading Methods: Manual unloading, AGV tray unloading, ALS Plus trolley insertion unloading, robotic arm vacuum suction unloading, and robotic arm targeting of materials

- Tofflon's flagship overturning plate freeze dryer offers unique advantages:-Utilizing the shelf as a tray allows for 100% effective space utilization, enabling direct injection of drug substance into the shelves for freeze-drying. This direct heat transfer increases production efficiency and effectively shortens production cycles.-By eliminating upstream processes such as tray cleaning, sterilization, and aseptic transfer, sterile risks are reduced, production efficiency is enhanced, and operational costs are lowered.-The overturning plate freeze dryer features closed loading or robotic arm feeding, with an automated door design that facilitates fully automated, unmanned operations, thus minimizing the risk of human intervention in sterile processes.

- With 30 years of experience in the freeze-drying industry and over 8,000 successful installations, we offer customized, high-quality, and highly stable solutions tailored to various product application scenarios.

- The core of freeze-drying lies in the "freeze-drying process." At Tofflon, we not only manufacture freeze dryers but also specialize in freeze-drying technologies. We have established the first domestic freeze-drying process laboratory, aiding enterprises in refining and optimizing their freeze-drying processes, ultimately reducing processing times.

-

Pharmaceuticals

-

Probiotics

-

Health Supplements

-

Medical Aesthetics

-

Food