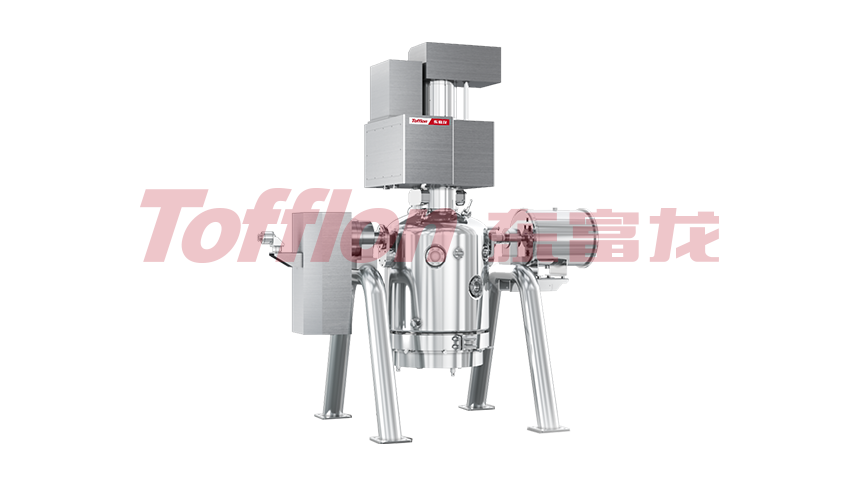

Rotary Filtration Cleaning Dryer

In the post-treatment process of pharmaceutical and other fine chemical production process, often filtration, washing, drying and other unit operations, in order to overcome the problems and shortcomings of the above unit equipment combination, while meeting the pharmaceutical industry to high-quality, high value-added, multi-variety change, multi-functional equipment integrated with filtration, washing and drying was born. Since the 1960s, Italy, Switzerland, Germany, France, Japan, Russia and other countries have developed filter dryers, in the actual production application, due to the technical limitations of equipment, there are a lot of material residues, liquid leakage, low drying efficiency and manual intervention risks, these risks also troubled many pharmaceutical practitioners. From the 1960s, Italy OMCA ,starting from the source of the problem, the filtration washing and drying equipment to do subversive technological innovation, developed a rotary multi-functional filtration washing and drying equipment, after more than half a century of technical precipitation and continuous improvement, The new rotary multifunctional filtration washing and drying equipment has been widely used and recognized in the European and American markets and the Indian market. The new multi-functional filter washing dryer simplifies the design through technological innovation, and solves a series of risks such as large residual amount, low drying efficiency and leakage of traditional filter washing and drying equipment, thereby improving the quality of the production of drugs and more in line with the requirements of regulations. Tofflon highlights international exchanges and cooperation and the protection of intellectual property rights, focuses on the development of new technologies and new application fields, introduces the Italian OMCA new rotary multi-functional filtration washing and drying equipment technology concept, jointly promote the development and promotion of equipment localization, equipment in the production and application of high yield, high efficiency, high quality characteristics. Leading the new trend of high value-added API production.

- High absorption.

- High efficiency.

- High quality.

- CIP/SIP

-

1.Sterile APIs.

-

2.High potency active/anti-tumor API

-

3.biomedical API:Heparin sodium/Insulin/Sodium Hyaluronate

-

4.Preparation auxiliary:microsphere/microcrystal /suspensions sterile API