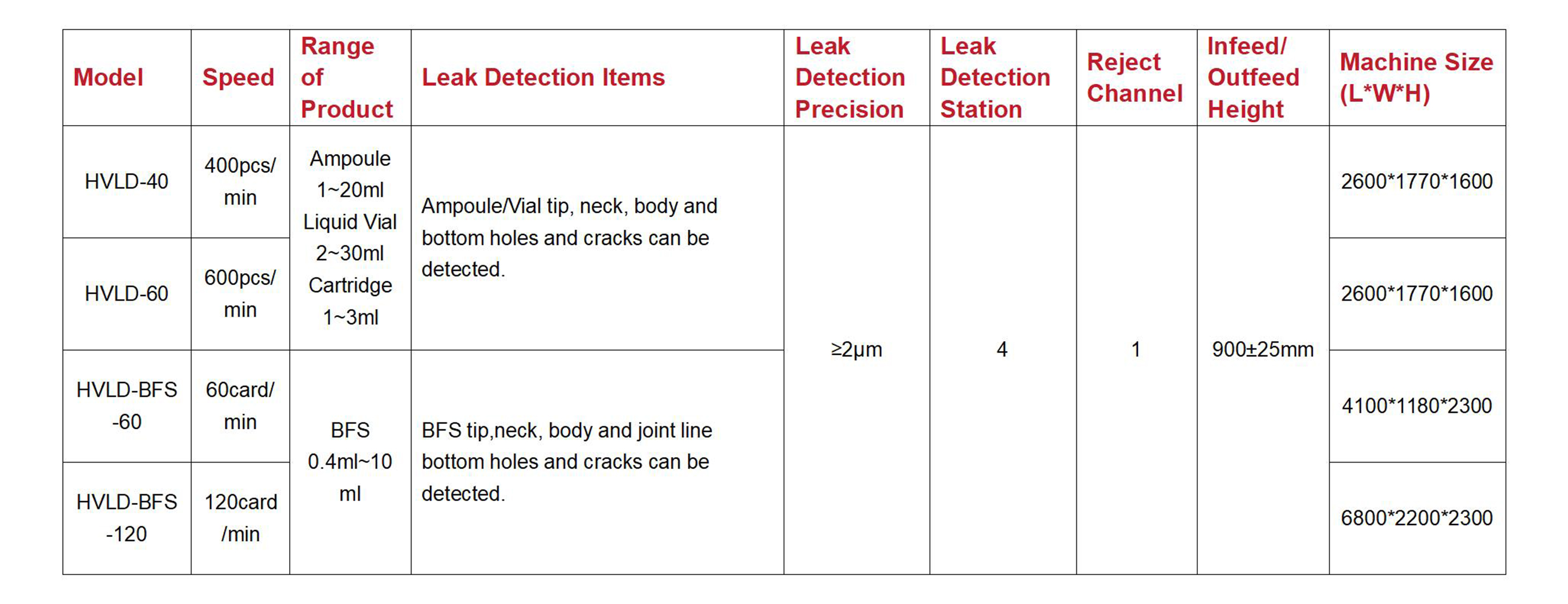

High Voltage Leak Detection Machine

The High-Voltage Discharge Leakage Testing Machine is powered by a dedicated high-voltage power supply, designed specifically for testing the integrity of seals on containers. The machine includes four dedicated detection stations, each responsible for conducting integrity tests on the seals of containers, such as liquid vials, BFS (Blow-Fill-Seal) containers, and others. The bottom seal of each bottle is thoroughly examined for any leakage or imperfections, ensuring the container's seal meets stringent quality standards. This technology is primarily used for Container Closure Integrity Testing (CCIT), a critical application in the pharmaceutical industry to guarantee the safety and efficacy of packaged product.

- The location of all detection stations can be adjusted according to products of different sizes.

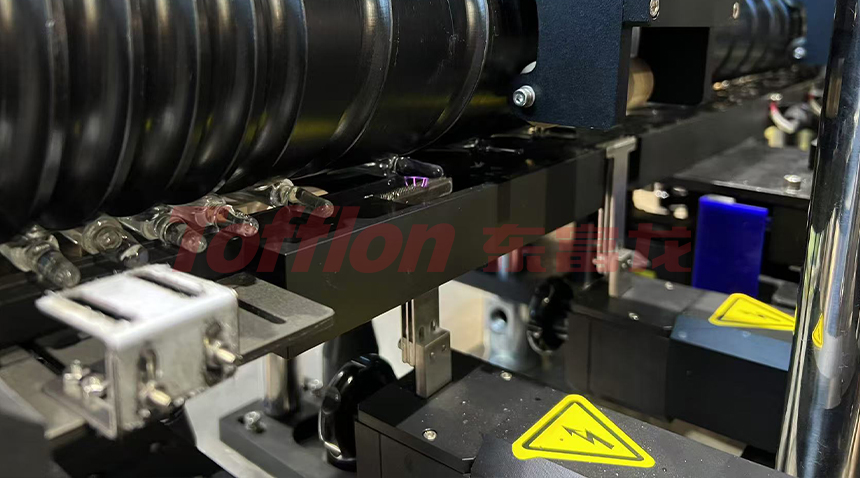

- A high voltage is applied in a specific area on the container to pass through the inspection electrode. When a leak exists in a container, the flow (liquid)will move through the hole. The current that passes through the container and the conductive solution will then be collected at the detection electrode). Tofflon’s HVLD has four detection heads, including tip, neck, body and bottom. All holes and cracks can be detected up to 2 μm.

-

Liquid Ampoule

-

Liquid Vial

-

PFS(Pre-filled Syringe)

-

BFS(Blow-Fill-Seal)

-

Cartridge