Purified Water Generation System

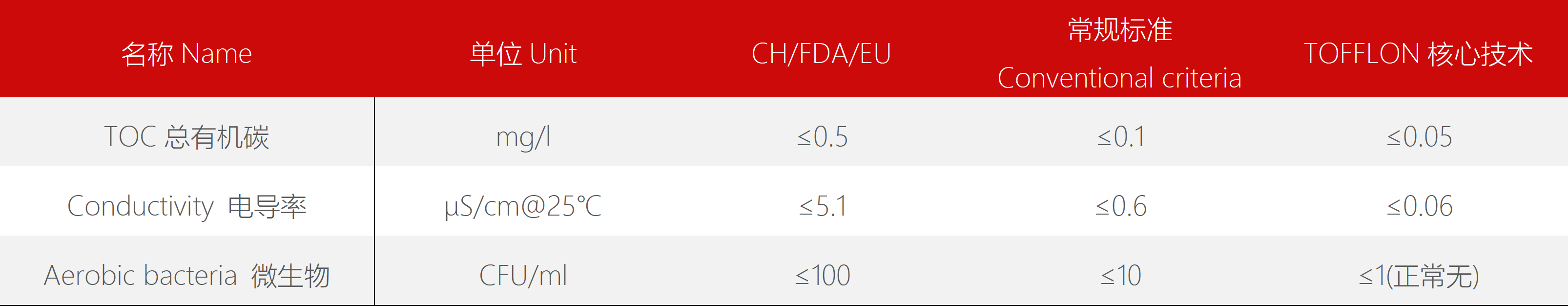

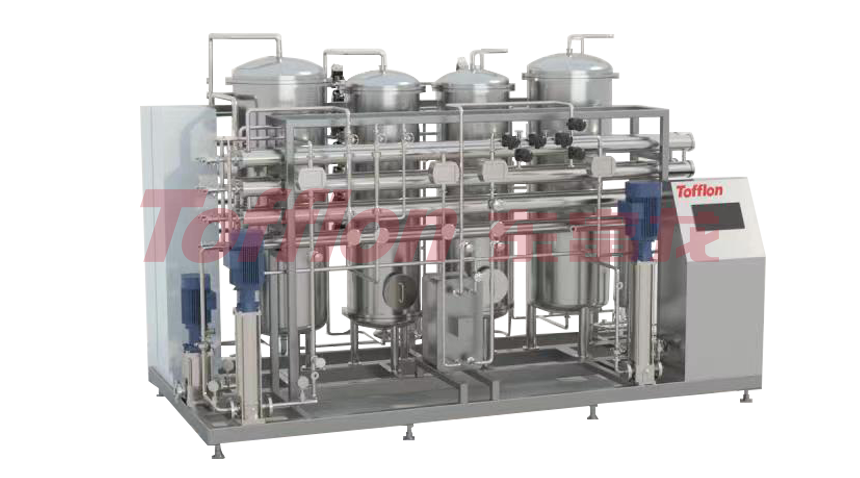

The Tofflon purified water preparation system develops different purified water production process plans for customers based on the water quality of different raw water (urban water and groundwater), including multiple combination forms such as secondary RO, RO+RO+EDI, RO+RO+EDI+UF, etc. The water quality of the produced water meets the regulatory requirements of cGMP, FDA, EU, WHO, PIC/S, etc; The whole machine adopts a modular production mode, with a reasonable and compact product structure, which is convenient for daily operation and maintenance. The equipment is designed with a pry off design, and customized water production equipment is provided, which can provide a brand new leading water production process. The main process flow is: raw water tank → raw water pump → multimedia filter → softener (UF) → activated carbon filter (medium pressure UV optional) → security filter → primary high-pressure pump → primary reverse osmosis → secondary high-pressure pump → secondary reverse osmosis → EDI → UF

- 1.Double-Pipeline water supply can effectively inhibit the growth of microbial in the piping.

- 2.Freshwater flushing can effectively prolong the service life of RO membrane.

- 3.Pre-treatment includes MMF,ACF,SF are designed with Pasteurization. The process can be sanitized separately or together for energy saving.

- 4.Medium pressure UV lamp s used to eliminate residual chlorine, to save the space, to avoid the replacement activated carbon, to save the labor cost and to inhibit the microbial growth.

- 5.RO concentrated water recycling system is environment friendly and energy saving.

-

1.Purified water demand from pharmaceutical companies, hospitals, medical device production, etc.

-

2.Water demand for processes such as electronic workshops and instrument factories.

-

3.Water demand for processes such as food production workshops.

-

4.Purified water demand in cosmetics production workshops, etc.

-

5.Purified water demand for biological laboratories, etc.