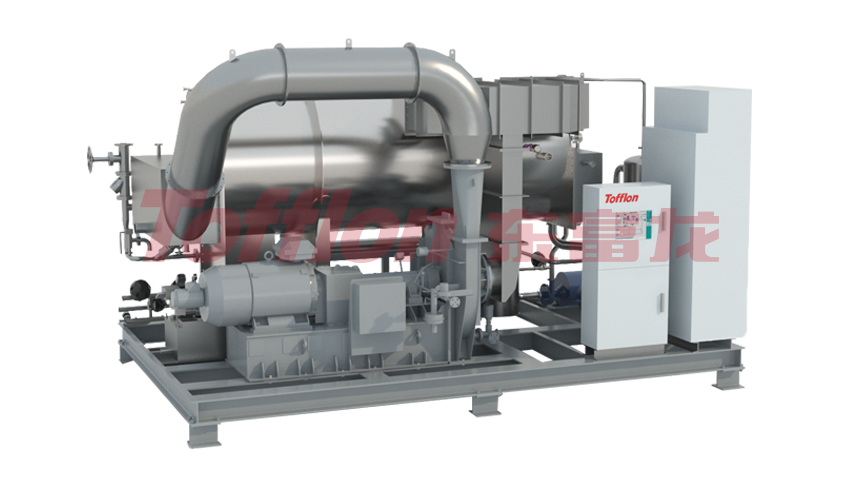

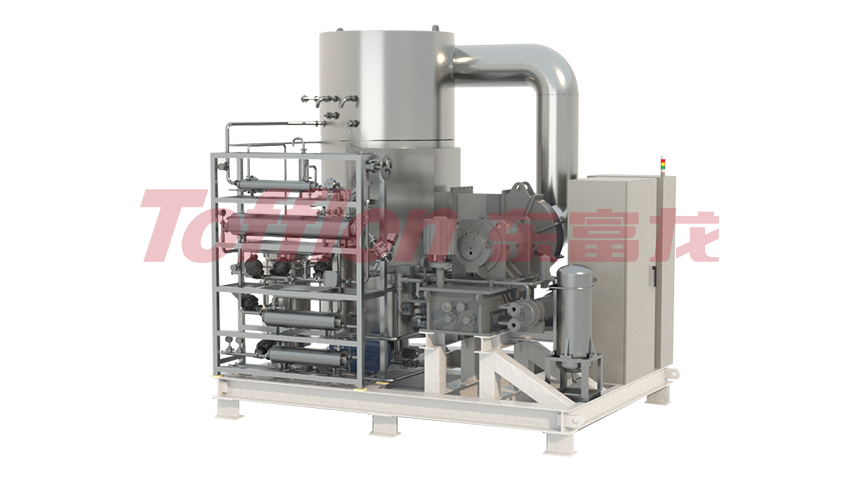

Vapor Compression Still

Tofflon Vapor Compression Still provides customers with high-quality injection water based on purified water as injection water as raw material water. The water production quality meets the regulatory requirements of cGMP, FDA, EU, WHO, PIC/S, etc; The entire machine adopts a modular design, with a reasonable and compact product structure. The equipment is designed for prying and easy daily operation and maintenance. The steam compression distilled water machine uses evaporation/condensation to produce injection water. According to the liquid level in the evaporator, the control system controls pure water to enter the hot press distilled water machine, mix with the recycled water in the equipment, and spray it into the evaporator. The evaporator is designed as a horizontal tube falling film type, with pure water evenly distributed on the outside of the heat exchange tube, and heated steam inside the tube. Pure water is heated and evaporates, while non evaporated pure water continues to circulate. The steam generated by evaporation is skimmed by gravity, skimmed by the wire mesh, and then sucked away by the steam compressor. After heating and boosting, it is transported to the interior of the heating tube to release heat and be recycled for secondary use.

- 1. Meet the requirements of FDA/GMP/EU and other pharmacopoeia;

- 2. Purified water is more than 10 times higher than traditional water quality standards in the system;

- 3. Compared to traditional energy-saving methods, the energy-saving efficiency is over 70%;

- 4. Large scale production of 3-35T/hr;

- 5. International biopharmaceutical companies prefer injection water preparation systems;

- 6. German original third-generation compression technology;

- 7. Effectively reduce the risk of red rust growth in the injection water system;

- 8.106 ℃ low-temperature evaporation.

-

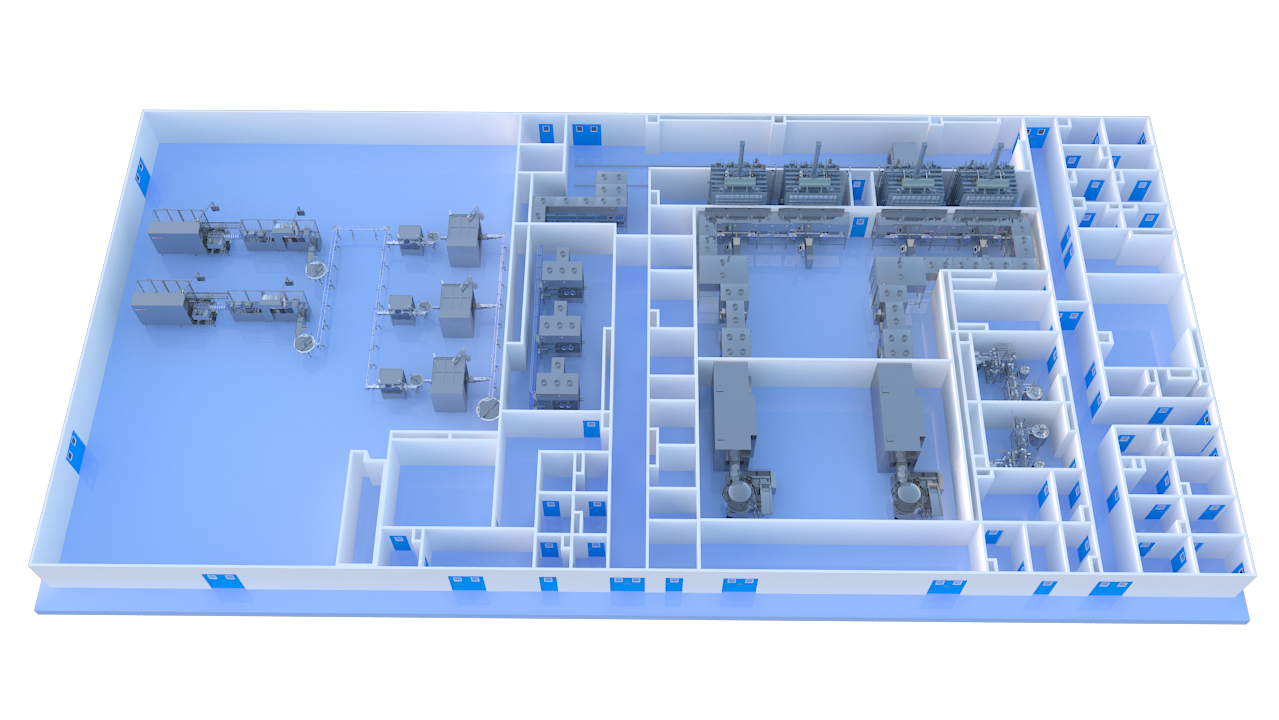

1.Demand for injection water from pharmaceutical companies, hospitals, medical device production, etc.

-

2.Water demand for processes such as food and drinking water production workshops.

-

3.Injection water demand in biological laboratories, etc.