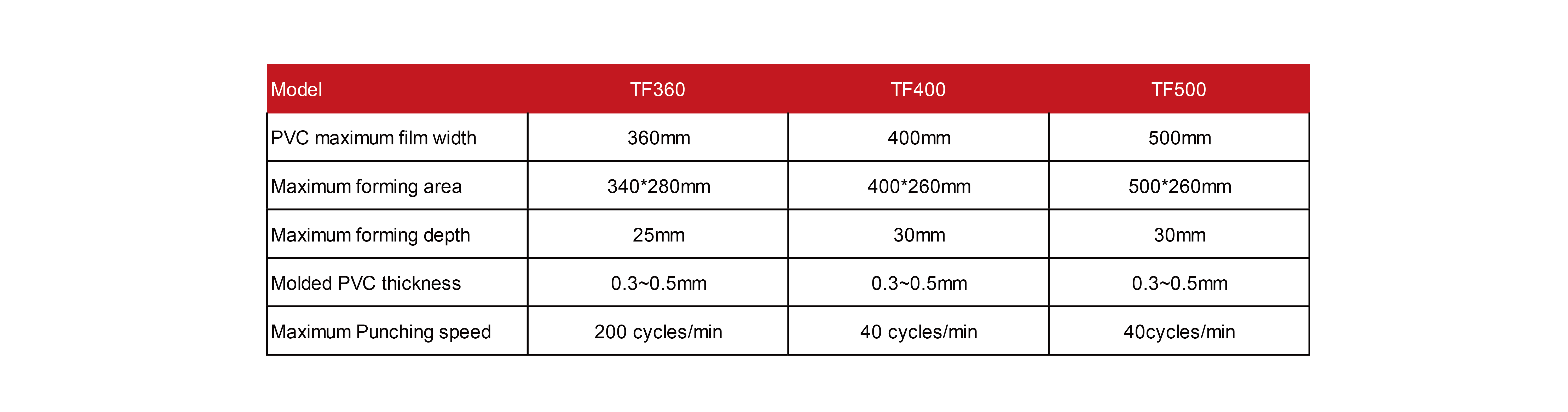

Flat Plate Blister Machine

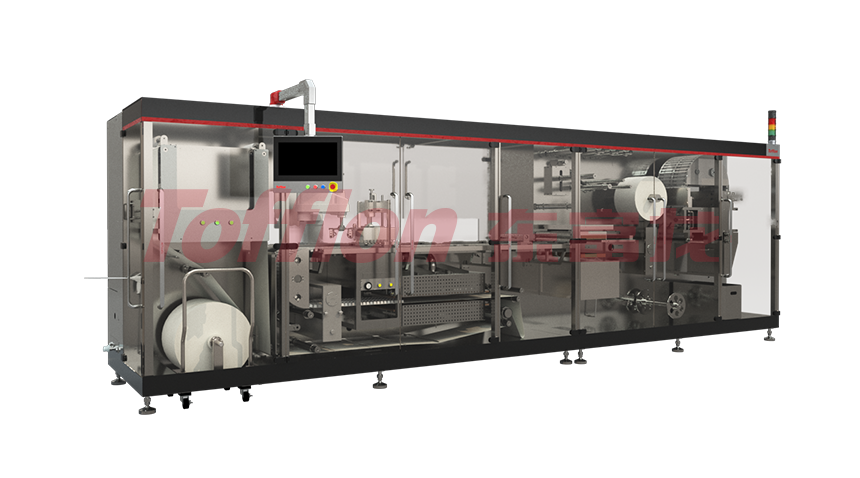

The flat plate forming and sealing blister machine is highly suitable for the parenteral products packaging such as PFS , Vial , Ampoules and cartridges . The equipment is servo-driven with full PLC and HMI control with high speed feeding technology . The equipment mainly consists of heating area , forming area , traction area , sealing area , punching area , and product detection . TF360 model with it’s compact footprint can realize the highest speed blister packaging , and save 10% of the blister packaging material with no waste edge punching mechanism . This equipment has reserves for eye-mark registration system , printing station & perforation station that provides the possibility to add the future functional options . Different kind of packaging materials for forming and sealing can be used in the same equipment.

- Non-stop roll change design with automatic film recovery.

- Quick format changeovers for different packaging size adjustment.

- Advanced feeding technology, that can achieve a speed of 400 (single packaging) with single station.

- Full servo control with dedicated digital technologies such as HMI and PLC.

- Stations can be reserved for online blister coding , Eyemark registration , & Peforation without increment in equipment footprint.

-

Vial

-

BFS

-

PFS

-

Ampoule

-

Other products