Disc Centrifuge

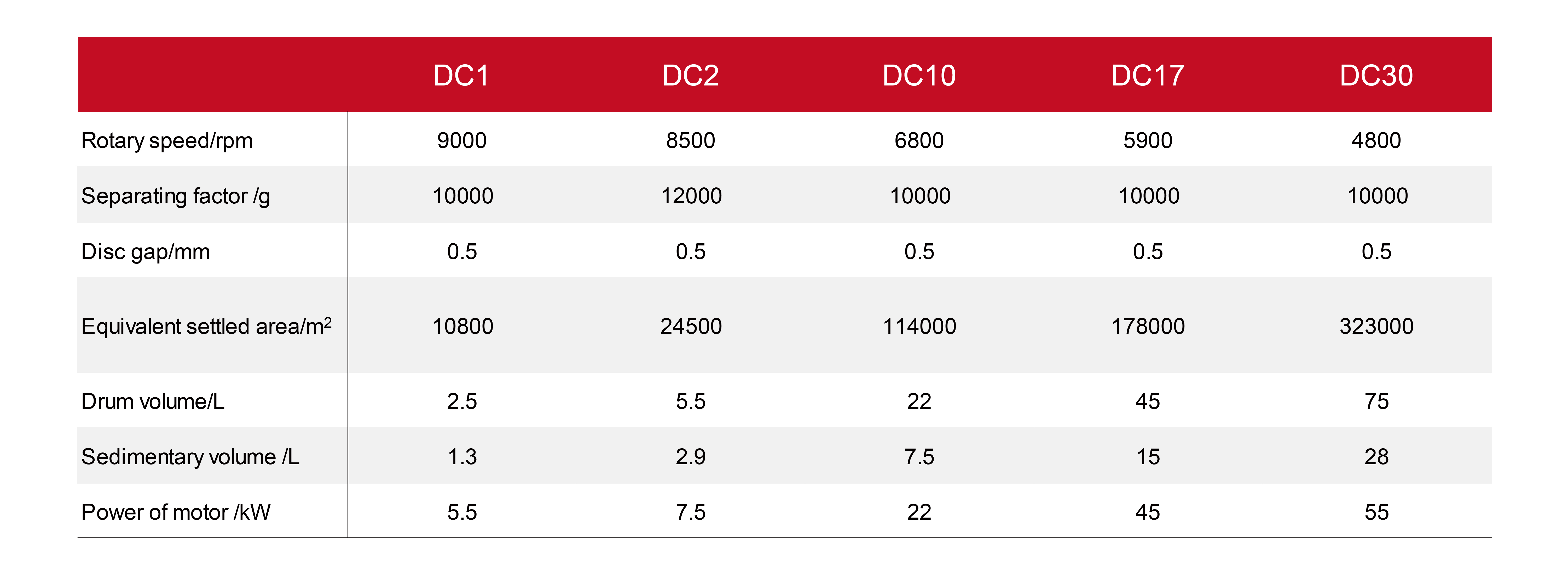

Disc centrifuges are used to continuously separate liquid-solid or liquid-liquid mixtures by physical means. Compared to other separation equipment (e.g. horizontal spiral centrifuges, flip bag centrifuges, etc.), disc centrifuges have a higher separation factor and a larger settling area, which enables the efficient separation of extremely fine solid particles/droplets from the mixture. Disc centrifuge equipment, systems and services are specifically designed to help customers improve/optimize the performance of their processes, and Tofflon provides solutions to help customers solve their separation, filtration and concentration challenges. Disc centrifuges and systems serve the biopharmaceutical, specialty probiotic and other industries, with capacities ranging from 300L/H in experimental models to 10,000L/H in industrial models. We works precisely with its customers to help them stay ahead of the curve.

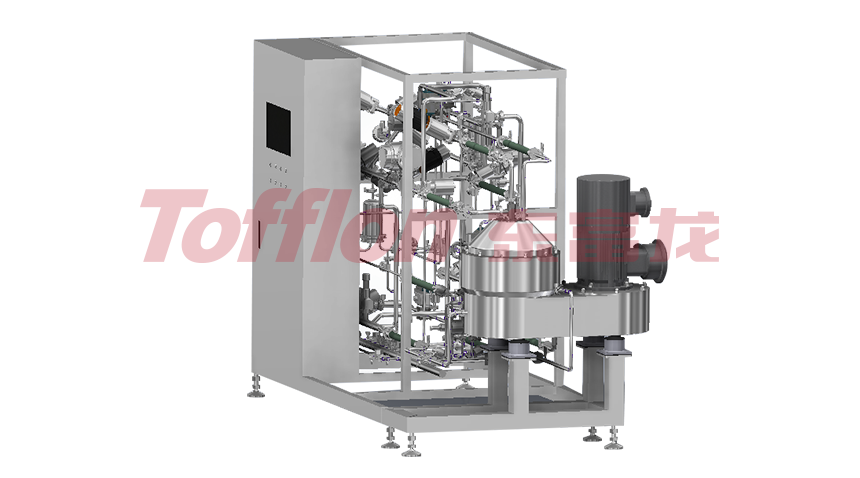

- Designed and developed according to high quality standards, it meets the hygiene requirements of biotechnology and pharmaceutical industry, capable of in-place cleaning and sterilization.

- Channel flushing combined with nozzle spray cleaning, so as to realize the online cleaning of the equipment.

- Double end mechanical seal, located in the operation water area, not in contact with the material area, to ensure the sealing performance of the equipment, and meets the requirements of on-line sterilization; After sterilization, automatic blowing and cooling are carried out,, and then close the system valve to maintain the equipment micro-positive pressure state, in order to prepare for production use.

- The disc rib adopts laser full welding, no cleaning dead corners.

- The speed of the equipment is adjustable, which can adapt to the needs of different production processes.

- The use of a scaler to precisely control the amount of discharge liquid injected, thus precisely controlling the opening time of the piston, so that the deviation of solid phase discharge is no more than 15%.

- Optimized feeding structure (feeding liquid seal, flexible feeding), feeding under the liquid surface while gradually accelerating through the inclined flow channel, reducing the shear crushing of materials.

- Modularized production piping design, complete the assembly and connection of all components within the module in Tofflon factory, shortening the customer's on-site construction and commissioning cycle.

-

Speciality Probiotics

-

Biomedicine (Blood Products)

-

Vaccines

-

Koji yeast

-

Insulin

-

Yogurt strains

-

Enzymes