Cleaning & Sterilization

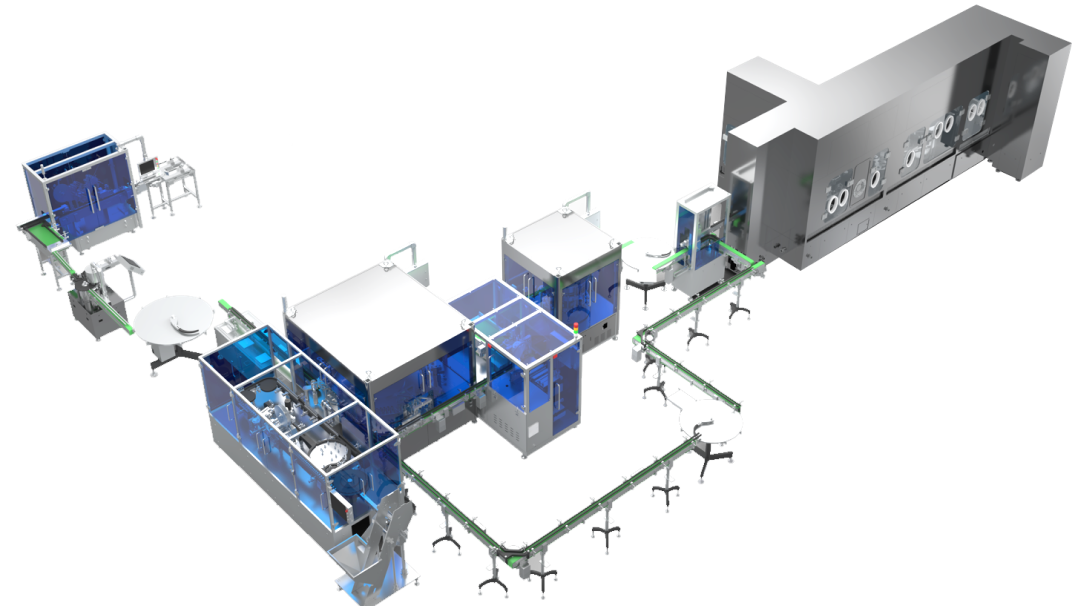

The rubber stopper and aluminum cap processing and transfer system is mainly used for the cleaning, sterilization and aseptic transfer of rubber stoppers and aluminum caps of injections in various filling forms such as vials, cartridge vials, pre-filled syringes and large-volume parenteral solutions. In response to the usage requirements of different application scenarios such as ORABS, CRABS and ISOLATOR, different specifications of rubber stoppers and aluminum caps as well as production batch requirements, and the restrictions on transfer methods caused by different room structures, it can provide multiple types of rubber stopper and aluminum cap processing and transfer systems, including the cage-type rubber stopper and aluminum cap cleaning machine, the RTP bucket-type rubber stopper and aluminum cap processing and transfer system, the automatic blanking system for sterile pipelines, and the hot-melt sealing system for sterile bags. With the 20 freeze-dried stoppers as the standard, the batch production volume can range from 10,000 to 240,000 pieces.

Advanced Production Base

(M+E+C)&AI&

Relying on the understanding of regulations and processes, provide reliable end-to-end equipment and facilities from R&D to commercialization; Through planning and design, procurement management, engineering construction, system verification and other processes, integrated delivery of factories with specific functions; Provide core process consumables such as culture medium, resin, filter and single use reaction bag to assist process optimization and solve the problem of stock solution production; Relying on the time experience of informationization and intelligence, we will provide forward-looking and professional digital intelligence planning to help enterprises transform digitally.

Address:

No.1509 Duhui Road,Shanghai,China,201108

Sales: info@tofflon.com | Service: service@tofflon.com

Copyright © Tofflon Science and Technology Group Co., Ltd. All Rights Reserved. Shanghai ICP No.2021035355-1

Privacy Policy