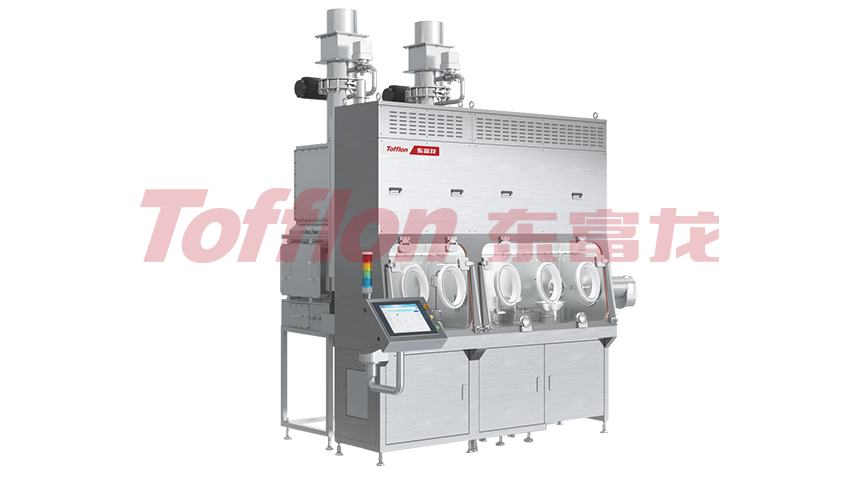

Sterility Testing Isolator

Sterility Testing Isolator is a device used for sterile testing of "test samples" based on Pharmaceutical Code Sterility Testing Requirements. As the drafter of China's sterile Isolator industry standards, the Sterility Testing Isolator provided by Tofflon is a human-machine separation and purification equipment that meets Grade A environmental requirements for sterile testing. The use of Tofflon Sterility Testing Isolator can reduce the requirements for the background environment level of sterile testing and greatly improve the reliability of sterile inspection results. The Tofflon Sterility Testing Isolator has functions such as rapid sterilization and modular assembly. The Tofflon Sterility Testing Isolator is currently widely used in the pharmaceutical industry, CGT industry, and related testing and drug inspection institutions. Tofflon Sterility Testing Isolator have passed international certifications such as CE and UL and are now widely used in the European and American markets.

- 1.New rapid hydrogen peroxide steam sterilization system, 20 minutes for the pass box chamber and 60 minutes for the Working chamber.

- 2.Online monitoring of all door openings and continuous monitoring of door gas seals.

- 3.Integration of hydrogen peroxide-resistant particles and planktonic bacteria, reducing the risk of incomplete sterilization of sampling lines.

- 4.Equipped with the Wireless Glove Integrity Testing System for wireless transmission and recording of test data.

- 5.Equipped with a new type of catalytic decomposition filter: This new type of catalytic decomposition filter is a high-efficiency catalytic decomposition filter successfully researched and developed by ‘Tofflon’ and Shanghai University. Equipped with the filter can effectively shorten the degradation time of hydrogen peroxide after sterilization and effectively reduce the concentration level of sterilization residue.

- 6.Compatible with Toxicity Protection to effectively prevent toxic or infectious samples from harming operators.

- 7.Adopting IPC control system and Siemens PLC, the pass box is fully automatic and intelligent control. On-line monitoring of parameters such as pressure, temperature, humidity, hydrogen peroxide concentration, etc. and intelligent alarms (e.g. abnormal door locks, abnormal temperature and humidity, high hydrogen peroxide residual concentration) can be realized.

- 8.The maintenance surface is front side, which does not require high space requirement in the laboratory.

-

1.QC laboratory.

-

2.Research laboratory.

-

3.Drug Testing Institute.