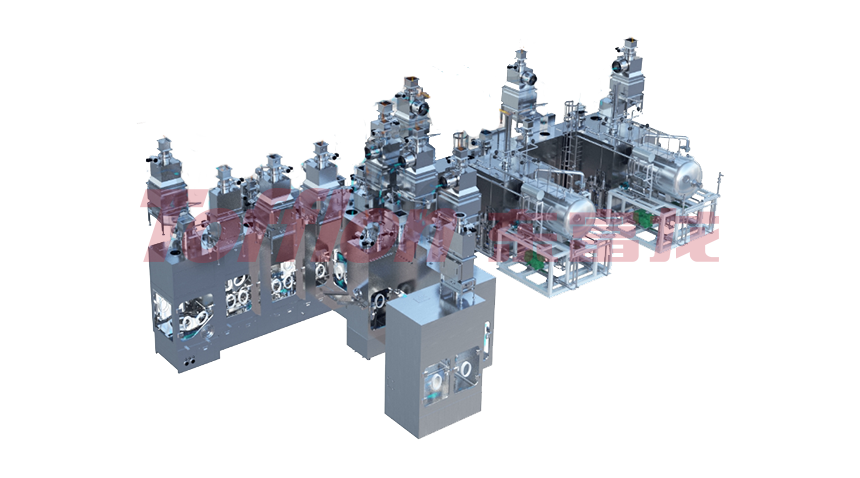

Pharmaceutical Isolator System

Barrier System has been used in the aseptic pharmaceutical industry since the 1980s. Pharmaceutical Isolator systems are integrated into aseptic filling equipment or other equipment to create a contained and controlled stability environment and ensure that personnel do not come into direct contact with the product during operation. In this way, aseptic filling with the Pharma Isolator System effectively reduces the risk of contamination and greatly improves the quality of pharmaceutical products. Since 2007, Tofflon has started to make innovations and breakthroughs in the research and application of aseptic Isolator system technology. At present, ‘Tofflon’ has become the largest supplier of Barrier System and Containment Solutions in China.

- Provides ultra-high level containment assurance: Provides containment chambers for Isolator of high volume production processes such as filling, freeze-drying, etc. (leakage rate can reach 1%/hr).

- Reliable and stable Grade A environment: The Isolator n system provides a reliable clean environment for products/processes that meets EU-GMP FDA class requirements.

- Built-in VPHP sterilization system eliminates bio-burden on chamber surfaces: integrated with Tofflon's latest patented hydrogen peroxide sterilization system for rapid sterilization.

- A variety of aseptic transfer options to meet the diversified production needs of customers: provide a variety of aseptic transfer options to meet the actual needs of customers.

- Independent temperature and humidity control method, the environment inside the chamber is not affected by the background environment: the integration of independent HAVC system can realize the temperature and humidity of the Isolator system is not affected by the background environment.

- Support for EI to enable rapid sterilization process development.

- Optimized airflow organization design based on CFD studies.

- Supports customized Isolator system design, providing customers with systematic containment and Isolator solutions.

- Remote ergonomics evaluation with VR platform.

-

1.COVID-19 vaccine production Isolator line.

-

2.ADC preparation production Isolator line.

-

3.Complex formulation production Isolator line.

-

4.Anti tumor production Isolator line.

-

5.CDMO production Isolator line.

-

6.Microsphere production Isolator line.